Chocolate is universally beloved, but it’s not the healthiest of foods and it’s not the most sustainable, either. Thanks to recent research, however, it’s about to become a little better. Scientists working in Switzerland (where else?) have found a way to make chocolate and include some of the cocoa pod into the recipe, adding more fiber and reducing the amount of sugar without changing the taste.

The history of chocolate goes back over 5,000 years. In those early days, chocolate would have looked very different. It was a beverage, often mixed with spices and used in rituals and medicinal practices. Chocolate was introduced to Europe in the early 16th century and became an instant hit in several countries. Europeans started mixing chocolate with milk and sugar, adding various flavors to it and ultimately turning it into the dessert we now know.

But chocolate may still be continuing its metamorphosis.

Chocolate fruits

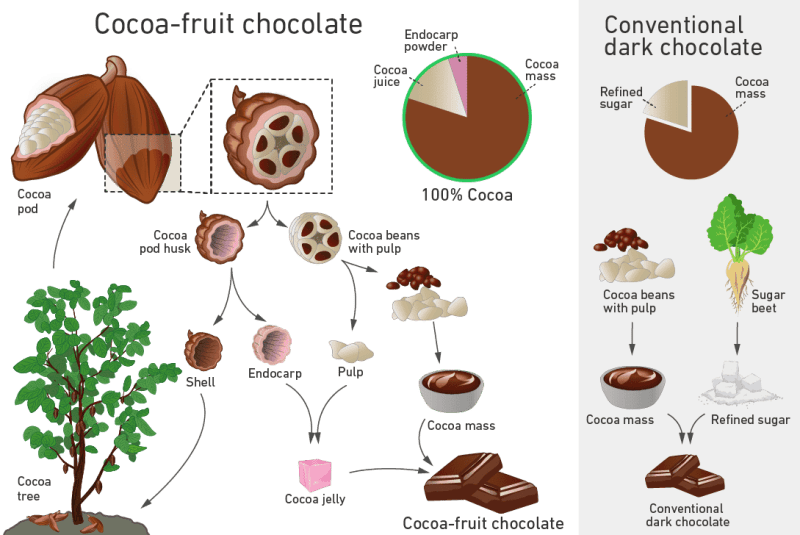

Chocolate is made from cacao beans, which are the seeds of the Theobroma cacao tree. The process begins with harvesting cacao pods, extracting the beans, and fermenting them to develop flavor. After fermentation, the beans are dried, roasted, and cracked to remove the nibs, which are ground into cocoa mass. This mass is then separated into cocoa solids and cocoa butter through a process called pressing.

Traditional chocolate production primarily uses cocoa beans and discards the rest of the cocoa pod. This process is not only wasteful but also contributes to environmental degradation.

The cacao fruit is a bit similar to the honeydew melon, says Kim Mishra, main author of the study. So it’s a bit like discarding all the delicious and nutritious part of the pulp and only using the seeds.

“These fruits have similar structures. Both have a hard outer shell that reveals the flesh of the fruit when cut open, as well as the cocoa beans or melon seeds and pulp in the interior.”

The problem is that incorporating the cocoa pulp into the chocolate making process is very tricky. Now, the researchers have developed a method to add the often-discarded pectin-rich cocoa pod endocarp into chocolate, creating a gel using cocoa pulp juice concentrate to replace traditional sugar.

Chocolate and gel

The novel chocolate formulation contains up to 20% gel, providing a sweet taste comparable to traditional chocolate. However, it offers improved nutritional value with higher fiber content and reduced saturated fatty acids (SFAs). Conventional chocolate is high in sugar and SFAs, which are linked to type 2 diabetes and cardiovascular diseases. By reducing these unhealthy components, the new chocolate formulation presents a healthier alternative.

To reach this result, researchers tested the texture of various chocolate compositions. Too much pulp and the chocolate would end up with a clumpy texture — too little, and the result isn’t sweet enough. It took several formulations, but ultimately, the team reached the right mixture of texture and sweetness.

The resulting chocolate has 15 grams of fiber per 100 grams of product (compared to the regular 10-12 grams) and only 23 grams of unhealthy saturated fats (as opposed to the usual 33 grams). More fiber and less saturated fats are exactly what health-focused consumers should be interested in.

“Fibre is valuable from a physiological perspective because it naturally regulates intestinal activity and prevents blood sugar levels from rising too rapidly when consuming chocolate. Saturated fat can also pose a health risk when too much is consumed. There’s a relationship between increased consumption of saturated fats and increased risk of cardiovascular diseases,” explains Mishra.

The researchers employed a taste test to assess the sweetness of the new chocolate. The new chocolate was perceived as comparably sweet, despite having a lower sugar content. This suggests that the sweetening power of the gel is effective in mimicking the sweetness of conventional sugar.

Better for farmers as well

Chocolate production requires a lot of resources. A kilogram of chocolate requires about 10,000 liters of water and emits 2.9–4.2 kg of CO, about as much as driving a car some 40 km. The majority of environmental impacts in chocolate production occur at the farm level, particularly due to land-use changes for cocoa cultivation. By utilizing more parts of the cocoa pod, the new chocolate formulation reduces the need for additional land, thereby lowering the overall environmental impact.

Cocoa farming, predominantly done by smallholder farmers in high-biodiversity regions, is fraught with trade-offs between productivity, environmental impact, and socio-economic sustainability. The new chocolate production method offers income diversification opportunities for farmers by providing a market for cocoa pod waste, potentially leading to socio-economic benefits in cocoa-producing regions.

“A cradle-to-factory life cycle assessment shows that large-scale production of this chocolate could reduce land use and global warming potential compared with average European dark chocolate production,” the researchers write.

But as it often happens, these innovations won’t necessarily hit the shelves anytime soon. Chocolate-making is a mature industry. Every change needs to happen carefully and gradually.

“Although we’ve shown that our chocolate is attractive and has a comparable sensory experience to normal chocolate, the entire value creation chain will need to be adapted, starting with the cocoa farmers, who will require drying facilities,” says Mishra. “Cocoa-fruit chocolate can only be produced and sold on a large scale by chocolate producers once enough powder is produced by food processing companies.”

Nevertheless, the mechanisms are already in motion. The researchers and their university, ETH, have already applied for a patent for their recipe. Ruby chocolate also emerged as a science-based innovation a few years ago, and is now becoming increasingly popular. The story of chocolate is still being written, and it’s as delicious as ever.

Journal Reference: Mishra K, Green A, Burkard J, Windhab E, et. al.: Valorisation of cocoa pod side streams improve nutritional and sustainability aspects of chocolate. Nature Food, 21. Mai 2024, doi: external page10.1038/s43016-024-00967-2call_made

Was this helpful?

Thanks for your feedback!

This story originally appeared on ZME Science. Want to get smarter every day? Subscribe to our newsletter and stay ahead with the latest science news.