As a child learning about basic engineering, you probably tried and failed to join a square-shaped toy with a circular-shaped toy: you needed a third shape to act as an adapter and connect them both together. On a much larger scale, integration of NASA’s powerful SLS (Space Launch System) rocket and the Orion spacecraft for the agency’s Artemis campaign would not be possible without the adapters being built, tested, and refined at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

Marshall is currently home to six adapters designed to connect SLS’s upper stages with the core stages and propulsion systems for future Artemis flights to the Moon.

Preparing Block 1 Adapters for Upcoming Crewed Flights

The first three Artemis flights use the SLS Block 1 rocket variant, which can send more than 27 metric tons (59,500 pounds) to the Moon in a single launch with the assistance of the interim cryogenic propulsion stage. The propulsion stage is sandwiched between two adapters: the launch vehicle stage adapter and the Orion stage adapter.

The cone-shaped launch vehicle stage adapter provides structural strength and protects the rocket’s flight computers and other delicate systems from acoustic, thermal, and vibration effects.

“The inside of the launch vehicle stage adapter for the SLS rocket uses orthogrid machining – also known as waffle pattern machining,” said Keith Higginbotham, launch vehicle stage adapter hardware manager supporting the SLS Spacecraft/Payload Integration & Evolution Office at Marshall. “The aluminum alloy plus the grid pattern is lightweight but also very strong.”

The launch vehicle stage adapter for Artemis II is at Marshall and ready for shipment to NASA’s Kennedy Space Center in Florida, while engineering teams are completing outfitting and integration work on the launch vehicle stage adapter for Artemis III. These cone-shaped adapters differ from their Artemis I counterpart, featuring additional avionics protection for crew safety.

Just a few buildings over, the Orion stage adapter for Artemis II, with its unique docking target that mimics the target on the interim cryogenic propulsion stage to test Orion’s handling during the piloting demonstration test, is in final outfitting prior to shipment to Kennedy for launch preparations. The five-foot-tall, ring-shaped adapter is small but mighty: in addition to having space to accommodate small secondary payloads, it contains a diaphragm that acts as a barrier to prevent gases generated during launch from entering Orion.

The Artemis III Orion stage adapter’s major structure is complete and its avionics unit and diaphragm will be installed later this year.

Unlike the flight hardware, the universal stage adapter’s development test article has flaws intentionally included in its design to test if fracture toughness predictions are correct. Technicians are incorporating changes for the next test article, including alterations to the vehicle damping system mitigating vibrations on the launch pad.NASA/Brandon Hancock

Following the first flight of SLS with Artemis I, technicians adjusted their approach to assembling the launch vehicle stage adapter by introducing the use of a rounding tool to ensure that no unintended forces are placed on the hardware.NASA/Sam Lott

The Orion stage adapter is complete at Marshall, including welding, painting, and installation of the secondary payload brackets, cables, and avionics unit. The adapter is protected by a special conductive paint that prevents electric arcing in space. NASA astronauts Reid Wiseman and Christina Koch viewed the hardware during a Nov. 27 visit to Marshall.NASA/Charles BeasonSLS Block 1B’s payload adapter is an evolution from the Orion stage adapter used in the Block 1 configuration, but each will be unique and customized to fit individual mission needs. “Both the Orion stage adapter and the payload adapter are being assembled in the same room at Marshall,” said Brent Gaddes, lead for the Orion stage adapter in the Spacecraft/Payload Integration & Evolution Office at Marshall. “So, there’s a lot of cross-pollination between teams.”NASA/Sam Lott## Block 1B Adapters Support Bolder Missions

Beginning with Artemis IV, a new configuration of SLS, the SLS Block 1B, will use the new, more powerful exploration upper stage to enable more ambitious missions to deep space. The new stage requires new adapters.

The cone-shaped payload adapter – containing two aluminum rings and eight composite panels made from a graphite epoxy material – will be housed inside the universal stage adapter atop the rocket’s exploration upper stage.

The payload adapter test article is being twisted, shaken, and placed under extreme pressure to check its structural strength as part of testing at Marshall. Engineers are making minor changes to the design of the flight article, such as the removal of certain vent holes, based on the latest analyses.

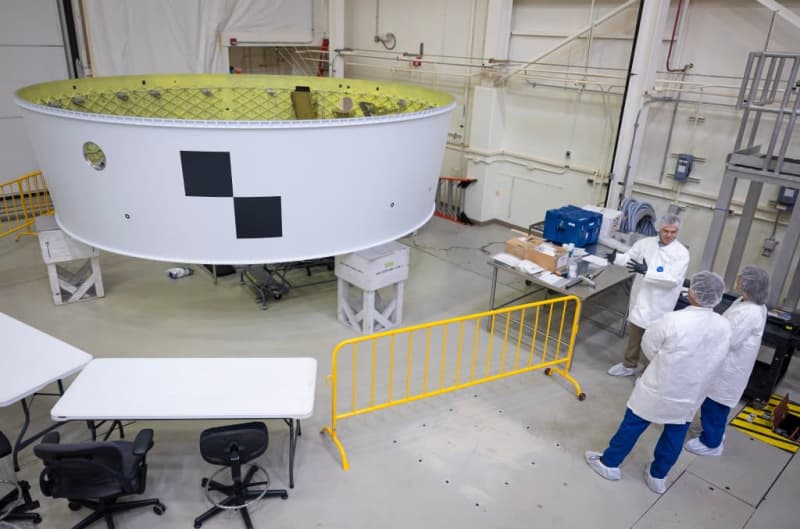

The sixth adapter at Marshall is a development test article of the universal stage adapter, which will be the largest composite structure from human spaceflight missions ever flown at 27.5 feet in diameter and 32 feet long. It is currently undergoing modal and structural testing to ensure it is light, strong, and ready to connect SLS Block 1B’s exploration upper stage to Orion.

“Every pound of structure is equal to a pound of payload,” says Tom Krivanek, universal stage adapter sub-element project manager at NASA’s Glenn Research Center in Cleveland. Glenn manages the adapter for the agency. “That’s why it’s so valuable that the universal stage adapter be as light as possible. The universal stage adapter separates after the translunar insertion, so NASA will need to demonstrate the ability to separate cleanly in orbit in very cold conditions.”

The Future of Marshall Is Innovation

With its multipurpose testing equipment, innovative manufacturing processes, and large-scale integration facilities, Marshall facilities and capabilities enable teams to process composite hardware elements for multiple Artemis missions in parallel, providing for cost and schedule savings.

Lessons learned from testing and manufacturing hardware for the first three SLS flights in the Block 1 configuration have aided in designing and integrating the SLS Block 1B configuration.

“NASA learns with every iteration we build. Even if you have a room full of smart people trying to foresee everything in the future, production is different from development. It’s why NASA builds test articles and doesn’t just start with the flight article as the first piece of hardware.”

BRENT GADDES

Lead for the Orion stage adapter in the Spacecraft/Payload Integration and Evolution Office

Both adapters for the SLS Block 1 are manufactured using friction stir welding in Marshall’s Materials and Processes Laboratory, a process that very reliably produces materials that are typically free of flaws.

Pioneering techniques such as determinant assembly and digital tooling ensure an efficient and uniform manufacturing process and save NASA and its partners money and time when building Block 1B’s payload adapter. Structured light scanning maps each panel and ring individually to create a digital model informing technicians where holes should be drilled.

“Once the holes are put in with a hand drill located by structured light, it’s simply a matter of holding the pieces together and dropping fasteners in place,” Gaddes said. “It’s kind of like an erector set.”

From erector sets to the Moon and beyond – the principles of engineering are the same no matter what you are building.

NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.