The Corvette team had been working on building prototypes of a mid-engine layout back in the 1960s, but it wasn’t until the eighth-generation C8 Corvette arrived in 2020 that the long-promised configuration for the car arrived. It turns out that the mid-engine layout got serious in the 2000s when the sixth-generation vehicle was in the works. But it was proving to be quite complicated, as GM’s financial troubles ultimately doused the plan, and the team was forced to pivot to a less-costly revamp of the C5 platform. Ultimately, a great car was still produced in the C6 Corvette, as seen in the legendary LS7-powered C6 Z06 and 638 hp C6 ZR1.

Mid-Engine Corvette: The 10 Year Journey

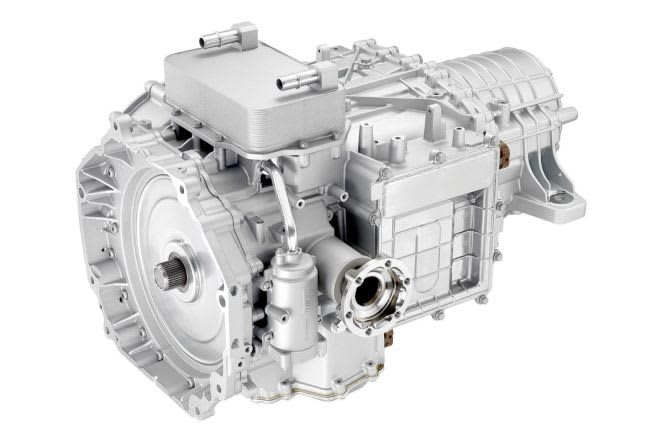

A vital component needed for the switch is the transaxle. A mid-engine car requires a rear transaxle rather than a longitudinal transmission. This makes the transaxle a foundational element and quite expensive since it’s highly specialized. Additionally, according to Design News, the team wanted to move to dual-clutch technology, which was in its early development at the time and added significant risk to the project. In 2006 and 2007, DCTs weren’t as prevalent as they are today, Porsche was the only company with a DCT at the time, and they were tailor-made for the brand’s signature flat-six engine.

So instead of going to a company, GM decided to design their own DCT with generation specifications such as the package space and what the engine outputs would be. Additionally, they wanted to add cylinder deactivation to improve fuel management. But that came with noise and vibration challenges. Corvette executive chief engineer Tadge Juechter pointed out that transitioning from not firing all cylinders to firing all cylinders results in torque bumps. Nobody had ever done anything where you would absorb the torque bumps with a friction clutch which brought about even more issues for the C6 development.

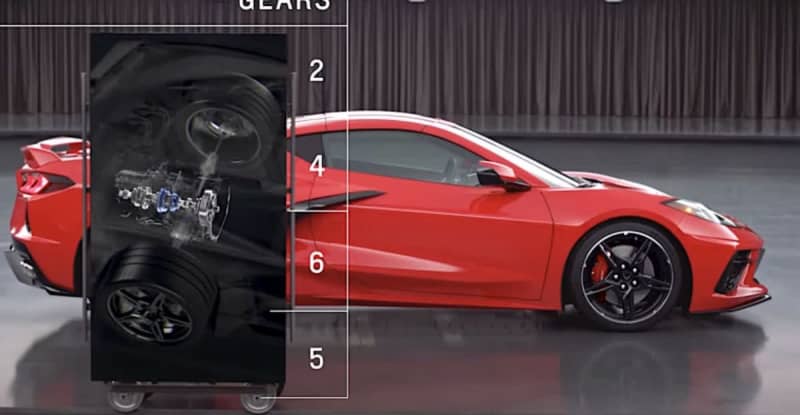

Ultimately, the the mid-engine Corvette C6 strategy was to have the engine go into the torque converter, the torque converter into the clutch, and clutches into the gears. Unfortunately, that ended up being a massive construction that continued to get bigger throughout the design process and, of course, extremely costly if the transmission didn’t work in the application, then the entire architecture would fail by the time investments were made in the plant and tooling.

Luckily, by 2016 the evolution of dual clutch transmissions had changed significantly, becoming more prevalent across the board, and knowledge regarding it had improved. At this time, C8 Corvette development was in the early stages. For the first mid-engined production Corvette, GM teamed up with Tremec, who saw that demand for manual transmissions were going down. Considering Tremec’s speciality in stick shifts, the company was highly motivated to get into the DCT business. Ultimately, the idea of a mid-engine Corvette with a dual clutch transmission was a go, roughly a decade after the original idea. That technology is currently best represented in the 670 horsepower 2023 C8 Corvette Z06 – the most sophisticated, most track-capable production Corvette yet. Just good luck getting your hands on one.