A “crazy idea” dreamt up during the Covid-19 lockdowns by University of Cambridge researchers has led to the creation of a low-cost, energy-efficient method for making material that can capture carbon dioxide (CO2) directly from the air.

They used a method similar to charging a battery but instead charged activated charcoal – often used in household water filters.

Charging a charcoal ‘sponge’ with ions that form reversible bonds with CO2, means they can successfully capture the gas directly from the air.

This could prove more energy efficient than current carbon capture approaches, as it requires much lower temperatures to remove the captured CO2 so it can be stored.

“Capturing carbon emissions from the atmosphere is a last resort, but given the scale of the climate emergency, it’s something we need to investigate,” said Dr Alexander Forse, from the Yusuf Hamied Department of Chemistry, who led the research.

“The first and most urgent thing we’ve got to do is reduce carbon emissions worldwide, but greenhouse gas removal is also thought to be necessary to achieve net zero emissions and limit the worst effects of climate change. Realistically, we’ve got to do everything we can.”

While direct air capture like that has been tried before, the current approaches are expensive, require high temperatures and the use of natural gas, and lack stability.

“Some promising work has been done on using porous materials for carbon capture from the atmosphere,” said Dr Forse. “We wanted to see if activated charcoal might be an option, since it’s cheap, stable and made at scale.”

Activated charcoal cannot normally capture and hold CO2 from the air, but Dr Forse and his colleague thought it might work if the activated charcoal was charged like a battery.

When a battery is charging, charged ions are inserted into one of the battery’s electrodes.

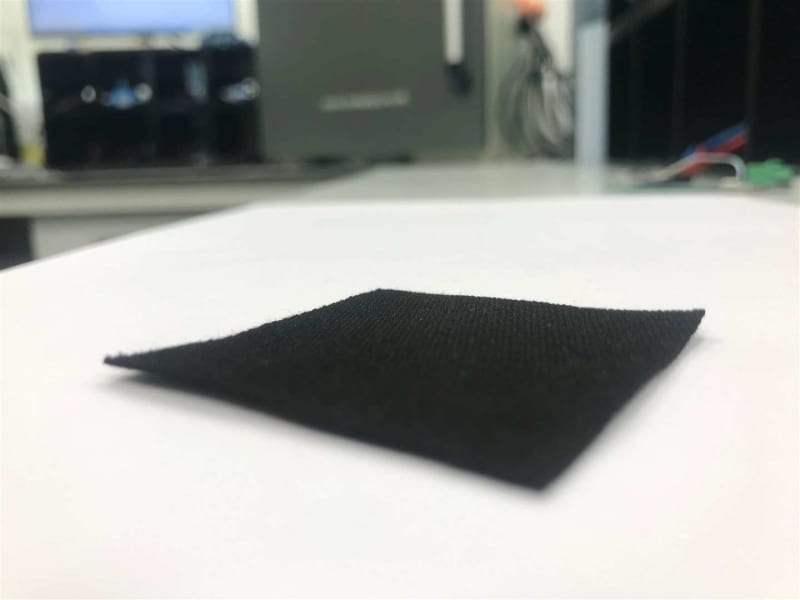

The researchers hypothesised that using hydroxides would make activated charcoal suitable for carbon capture, since these chemical compounds form reversible bonds with CO2. They charged an inexpensive activated charcoal cloth with hydroxide ions. Acting like an electrode in a battery, the hydroxide ions accumulated in the tiny pores of the charcoal.

At the end of the charging process, the charcoal can be removed from the “battery”, washed and dried.

Tests proved it can capture CO2 directly from the air.

“It’s a new way to make materials, using a battery-like process,” said Dr Forse. “And the rates of CO2 capture are already comparable to incumbent materials. But what’s even more promising is this method could be far less energy-intensive, since we don’t require high temperatures to collect the CO2 and regenerate the charcoal sponge.”

After capture, the CO2 needs to be purified and stored. For this, the material is heated to reverse the hydroxide-CO2 bonds.

While most materials currently used for CO2 capture from air need to be heated as high as 900°C, often using natural gas, this method required temperatures of only 90-100°C, which can be achieved using renewable electricity.

Resistive heating is used – essentially heats the material from the inside out – to make the process faster and less energy-intensive.

Currently the materials have their limitations.

“We are working now to increase the quantity of carbon dioxide that can be captured, and in particular under humid conditions where our performance decreases,” said Dr Forse.

But the method could also have applications beyond carbon capture, as the pores in the charcoal and the ions inserted into them can be adapted to capture a range of molecules.

“This approach was a kind of crazy idea we came up with during the Covid-19 lockdowns, so it’s always exciting when these ideas actually work,” said Dr Forse.

“This approach opens a door to making all kinds of materials for different applications, in a way that’s simple and energy-efficient.”

The research was reported in the journal Nature.

A patent has been filed and the research is being commercialised with the help of Cambridge Enterprise, the university’s commercialisation arm.