FlexEnable has started shipping the world’s first mass-produced consumer product incorporating organic transistor technology.

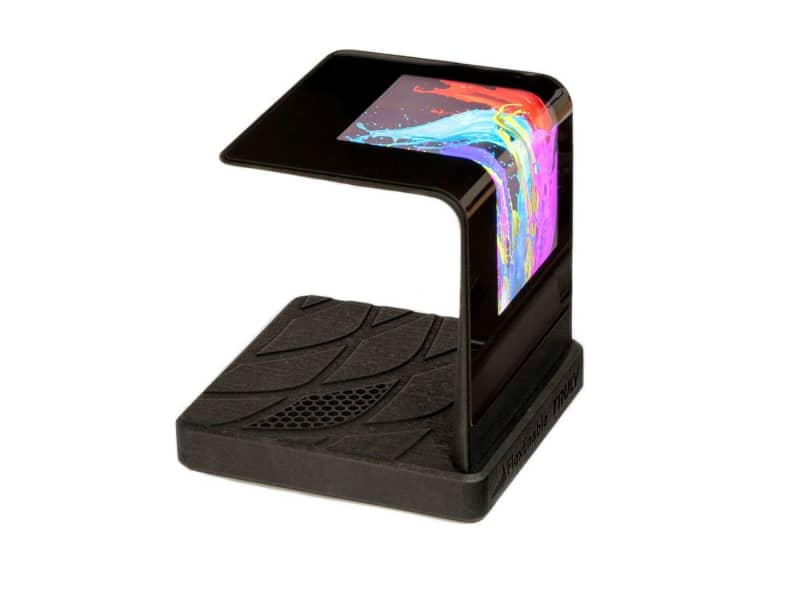

The device, called Ledger Stax, is a secure crypto wallet developed by French company and market-leader Ledger.

FlexEnable partnered with display manufacturing companies DKE (Shanghai) and Giantplus (Taiwan) to realise Ledger’s design for a credit card-sized product with an E Ink display uniquely wrapped around a 180-degree bend.

Flexenable has started shipping the world’s first mass-produced consumer product incorporating organic transistor technology.

The device, called Ledger Stax, is a secure crypto wallet developed by French company and market-leader Ledger. FlexEnable partnered with display manufacturing companies DKE (Shanghai) and Giantplus (Taiwan) to realise Ledger’s design for a credit card-sized product with an E Ink display uniquely wrapped around a 180-degree bend.

Ledger Stax uses highly flexible organic thin-film transistors (OTFTs) to deliver a display radius of curvature never before achieved in an ePaper display product. The OTFTs, comprise organic materials and process IP developed, supplied and licensed by FlexEnable.

Made of polymers instead of silicon, these OTFTs are manufactured directly onto plastic sheets instead of glass and are much thinner, lighter and shatterproof compared to today’s glass displays. With fully qualified manufacturing now underway at DKE and Giantplus, FlexEnable’s OTFT technology is the first and only organic transistor in mass production.

The manufacture of these flexible OTFT backplanes by Giantplus, a leading Taiwanese display maker, is paving the way for a new generation of flexible displays and optical modules with form factors not imaginable until now, with applications including AR/VR optics, ePrivacy screens, automotive smart windows and Organic LCDs.

Chuck Milligan, CEO of FlexEnable, said: “We are extremely proud to have collaborated with Ledger, whose innovative product design and dedication to bringing new technology to market have enabled us to achieve this breakthrough. We have also been very impressed by our partners DKE, who developed a volume production capability to achieve the first ever 180-degree bend lamination of flexible ePaper displays, and Giantplus, the first fab to implement our unique transistor materials and patented low-temperature process technology into mass production.

“The launch of Ledger Stax represents a significant milestone, not just for our company, but for the entire display industry, and the billon-dollar ePaper display market is just the beginning. As we ramp up production of FlexiOM materials to meet growing demand for Ledger Stax, the established supply chain is now primed to support a range of future applications in AR/VR optics and beyond, to meet the volume needs of our brand partners.”